产品概述:The high-voltage series reactor is mainly connected in series with the high-voltage parallel capacitor to limit the closing inrush current during the switching ···

The high-voltage series reactor is mainly connected in series with the high-voltage parallel capacitor to limit the closing inrush current during the switching process of the capacitor, suppress the grid voltage waveform distortion and control the harmonic component flowing through the capacitor, and eliminate the damage to the capacitor caused by harmonics and overcurrent. In addition, some power grids or electrical equipment are also connected to reactors for current limiting protection in order to limit the sudden change of current. With the continuous development of the power grid, as an indispensable device in the reactive power compensation device, high-voltage series reactors are used more and more widely.

Structural features | |

iron core | The iron core is made of high-quality cold-rolled silicon steel sheets coated with mineral oxides . The iron core column is made of epoxy resin vacuum casting, so that the air gap between the discs is closed by epoxy resin and a resin layer is formed on the surface of the core column, which effectively reduces the vibration between the core discs, thereby reducing noise and enhancing the Dielectric strength between the core and the coil. The surface of the iron core is sealed with F-grade epoxy resin, and anti-corrosion measures are taken to avoid rust. |

coil | The coil is an epoxy resin vacuum casting coil, and the inside and outside of the coil is reinforced with epoxy glass mesh cloth, and the F-grade epoxy resin is used for casting in a vacuum state. The coil not only has good insulation performance, but also has high mechanical strength, and can withstand large current shocks and thermal shocks without cracking. The epoxy casting coil is non-absorbent, has good moisture resistance, and has low local anti-electricity, which can operate safely in harsh environmental conditions. |

assembly | The end face of the iron core is made of high-quality silicon steel sheet end face glue, so that the iron core column and the iron ladle are firmly combined, which greatly reduces the noise during operation. Use an advanced pre-assembly system to inspect the assembly results of individual components in the assembly. Advanced vibration and noise reduction structure system, including: strong compression of upper and lower clips, elastic rubber pads between clips and coils, elastic rubber pads between clips and base. |

Parameters and Standards | |

Use environmental conditions | 1. The altitude does not exceed 2000 meters. |

2. The operating ambient temperature is -25℃~+45℃, and the relative humidity does not exceed 90%. | |

3. There is no harmful gas around, no flammable and explosive materials. | |

4. The surrounding environment should have good ventilation conditions. If it is installed in the cabinet, ventilation equipment should be installed. | |

other | |

download Google | 1. Product model |

2. Rated current | |

3. Rated voltage (grid voltage) | |

4. Rated inductance | |

5. Insulation class | |

6. Other special requirements can be specified in the agreement | |

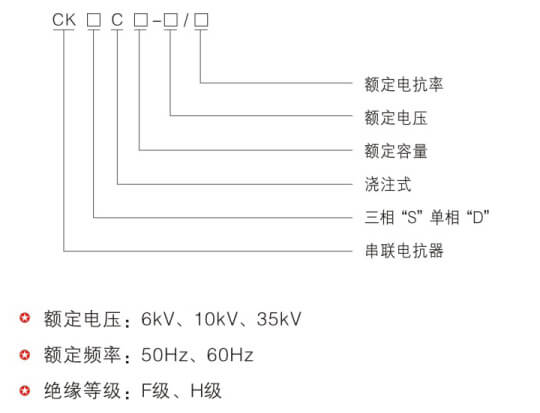

Model and meaning:

High voltage series reactor technical parameters | ||||||||||

Reactor Model | Rated capacity (kvar) | Rated voltage (kv) | Reactance rate % | Rated current (A) | L (mm) | W (mm) | H (mm) | A (mm) | B (mm) | Weight (kg) |

CKSC-30/6-5 | 30 | 6 | 5 | 52 | 930 | 590 | 1121 | 550 | 400 | 410 |

CKSC-36/6-6 | 36 | 6 | 6 | 52 | 930 | 590 | 1121 | 550 | 400 | 410 |

CKSC-45/6-5 | 45 | 6 | 5 | 79 | 960 | 590 | 1041 | 400 | 400 | 510 |

CKSC-54/6-6 | 54 | 6 | 6 | 79 | 960 | 590 | 1041 | 400 | 400 | 510 |

CKSC-60/6-5 | 60 | 6 | 5 | 105 | 970 | 590 | 1013 | 550 | 400 | 550 |

CKSC-72/6-6 | 72 | 6 | 6 | 105 | 910 | 740 | 1101 | 550 | 550 | 510 |

CKSC-75/6-5 | 75 | 6 | 5 | 131 | 910 | 740 | 1101 | 550 | 550 | 510 |

CKSC-90/6-6 | 90 | 6 | 6 | 131 | 940 | 740 | 1241 | 660 | 550 | 640 |

CKSC-120/6-5 | 120 | 6 | 5 | 210 | 1060 | 740 | 1261 | 550 | 550 | 830 |

CKSC-144/6-6 | 144 | 6 | 6 | 210 | 990 | 740 | 1261 | 550 | 550 | 790 |

CKSC-180/6-5 | 180 | 6 | 5 | 315 | 1120 | 740 | 1355 | 550 | 550 | 1080 |

CKSC-200/6-5 | 200 | 6 | 5 | 350 | 1260 | 850 | 1281 | 660 | 660 | 1200 |

CKSC-216/6-6 | 216 | 6 | 6 | 315 | 1200 | 740 | 1317 | 550 | 550 | 1055 |

CKSC-240/6-6 | 240 | 6 | 6 | 350 | 1200 | 740 | 1317 | 550 | 550 | 1075 |

CKSC-90/10-4.5 | 90 | 10 | 4.5 | 105 | 1050 | 740 | 1103 | 550 | 550 | 720 |

CKSC-108/10-4.5 | 108 | 10 | 4.5 | 126 | 1050 | 740 | 1163 | 550 | 550 | 800 |

CKSC-120/10-6 | 120 | 10 | 6 | 105 | 1030 | 740 | 1151 | 550 | 550 | 770 |

CKSC-135/10-4.5 | 135 | 10 | 4.5 | 157 | 1060 | 740 | 1163 | 550 | 550 | 790 |

CKSC-144/10-6 | 144 | 10 | 6 | 126 | 1060 | 740 | 1240 | 550 | 550 | 845 |

CKSC-162/10-4.5 | 162 | 10 | 4.5 | 189 | 1110 | 740 | 1181 | 550 | 550 | 930 |

CKSC-180/10-4.5 | 180 | 10 | 4.5 | 210 | 1210 | 740 | 1230 | 550 | 550 | 1280 |

CKSC-180/10-6 | 180 | 10 | 6 | 157 | 1090 | 740 | 1240 | 550 | 550 | 960 |

CKSC-189/10-4.5 | 189 | 10 | 4.5 | 220 | 1210 | 740 | 1285 | 550 | 550 | 1280 |

CKSC-216/10-4.5 | 216 | 10 | 4.5 | 252 | 1110 | 740 | 1286 | 550 | 550 | 1070 |

CKSC-216/10-6 | 216 | 10 | 6 | 189 | 1360 | 740 | 1265 | 660 | 660 | 1060 |

CKSC-225/10-4.5 | 225 | 10 | 4.5 | 262 | 1360 | 740 | 1381 | 660 | 660 | 1180 |

CKSC-240/10-6 | 240 | 10 | 6 | 210 | 1330 | 740 | 1126 | 660 | 660 | 1000 |

CKSC-240/10-12 | 240 | 10 | 12 | 96 | 1350 | 850 | 1266 | 660 | 660 | 1150 |

CKSC-243/10-6 | 243 | 10 | 4.5 | 283 | 1360 | 740 | 1148 | 660 | 660 | 1180 |

CKSC-252/10-6 | 252 | 10 | 6 | 220 | 1350 | 740 | 1186 | 660 | 660 | 1190 |

CKSC-270/10-4.5 | 270 | 10 | 4.5 | 315 | 1290 | 740 | 1353 | 660 | 660 | 1400 |